For Rally and Endurance usage, small European made engines typically have close to optimal runners as stock. Many Japanese engines have often too big runners to start with.

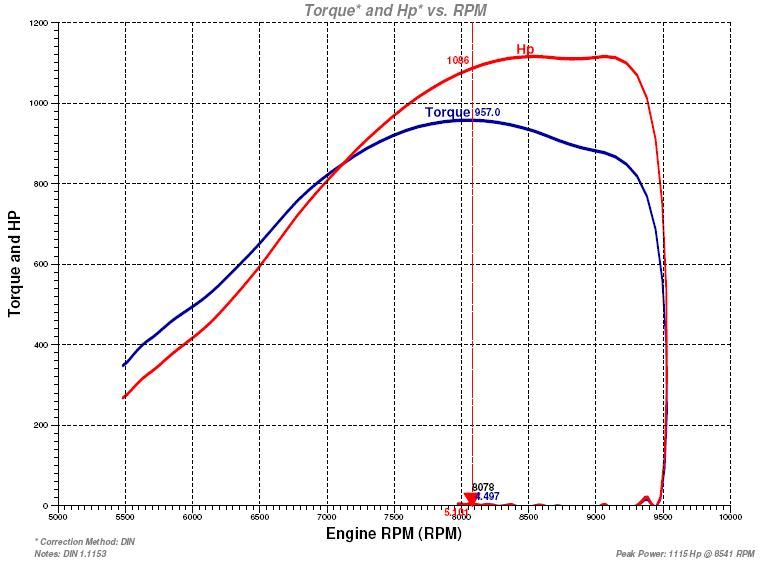

Getting good driveability and useable power range requires right sized ports. Too big ports make peaky power curve and cause driveability issues.

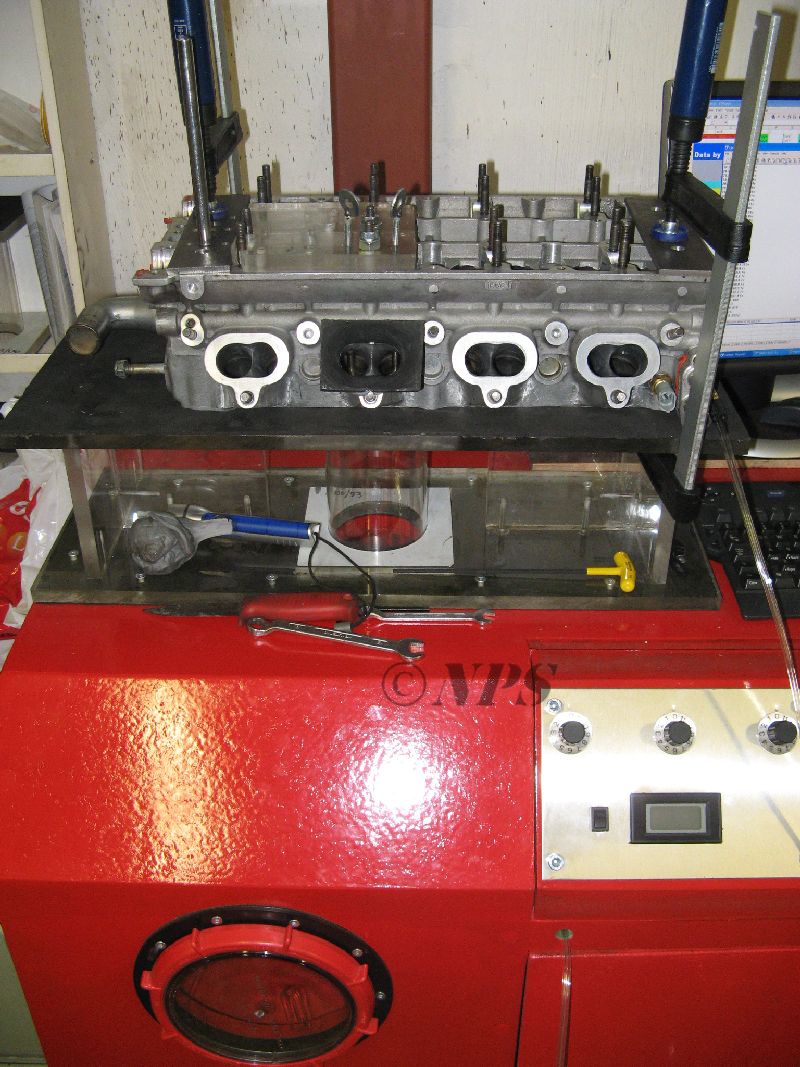

Small port size in diameter makes small changes to diameter big change in cross section area. For example cylinder head which starts with a 35mm port and cleaning up casting marks increases size to a 37mm will have 11.8% area increase. Similarly a 16 valve heads going from a 24mm diameter intake runner to a 26mm would be increase of 17.4%. That same percentual amount would be seen in flow speed as reduction. Therefore proper port sizing is essential and it is really easy to over size ports.

Chasing maximum flow numbers ends up many times having too big runners which do not work optimally.

High RPM high VE% engines live and die from runner sizes and pulse tuning, so do not hog them out.

We have some CNC porting offerings, you can find them from web shop side.

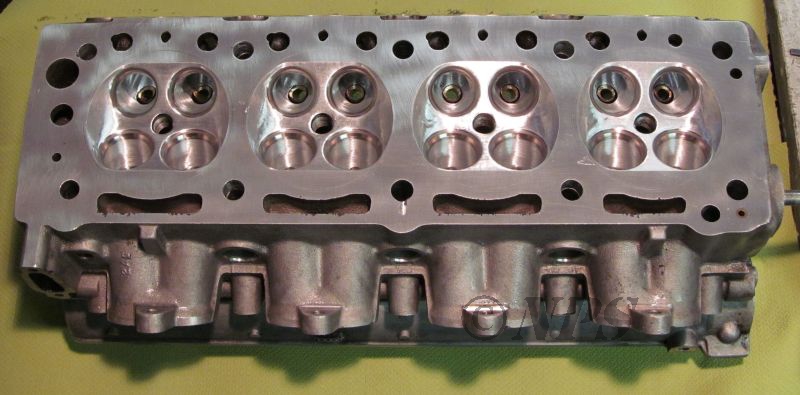

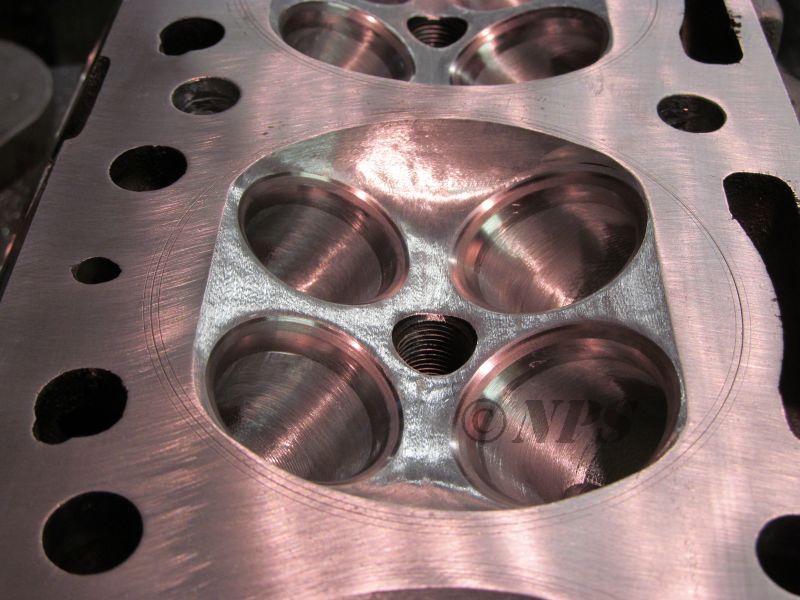

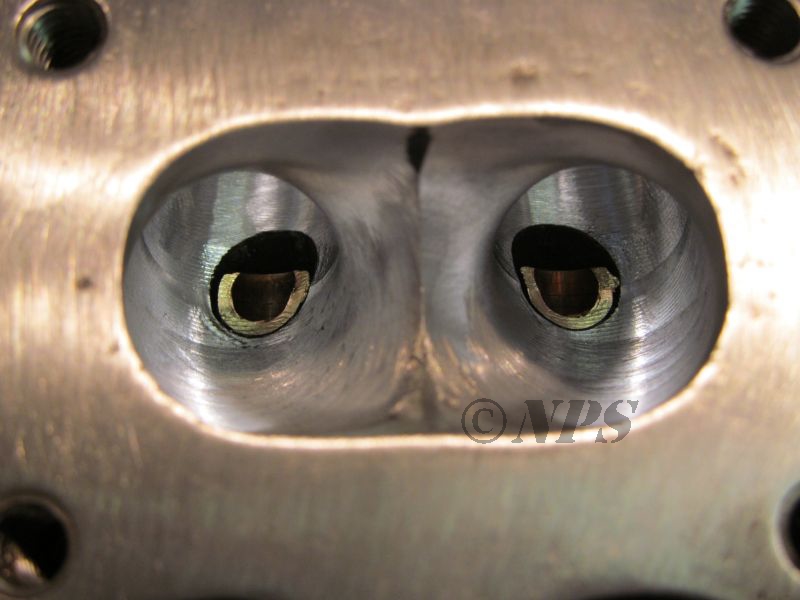

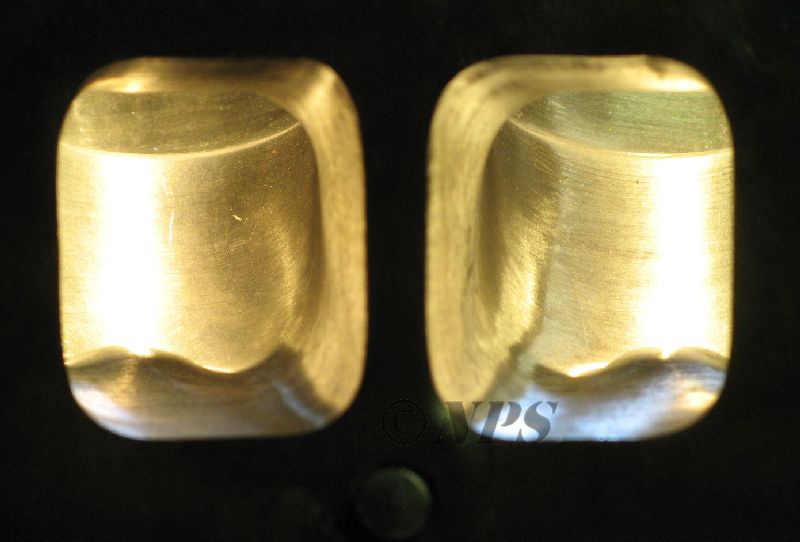

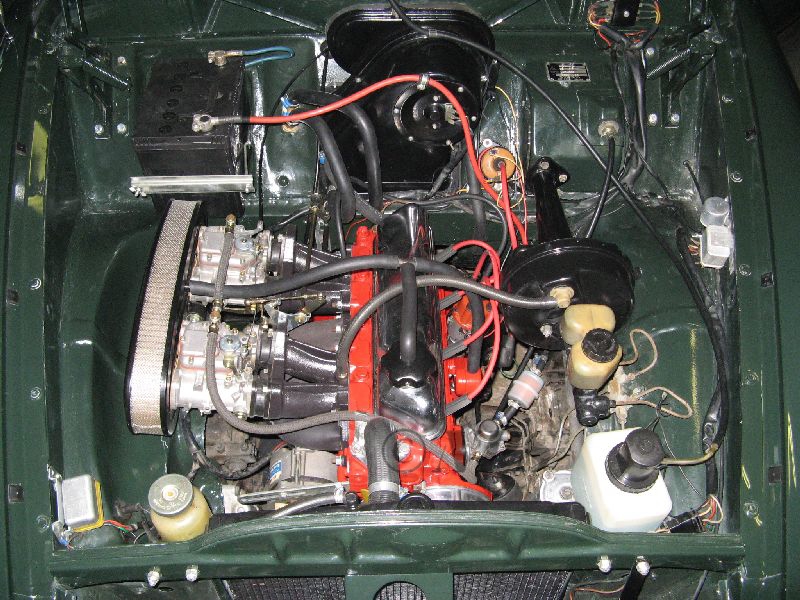

Examples of our work from past years:

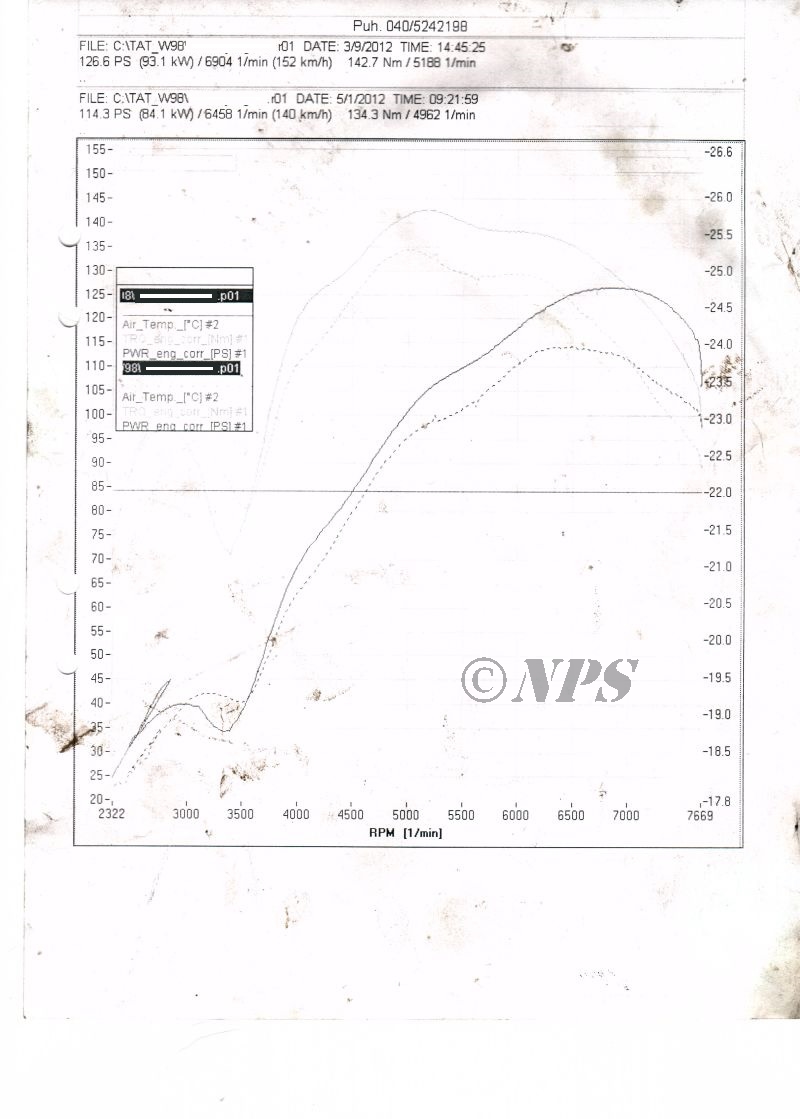

Audi 1.8t 20v AEB:

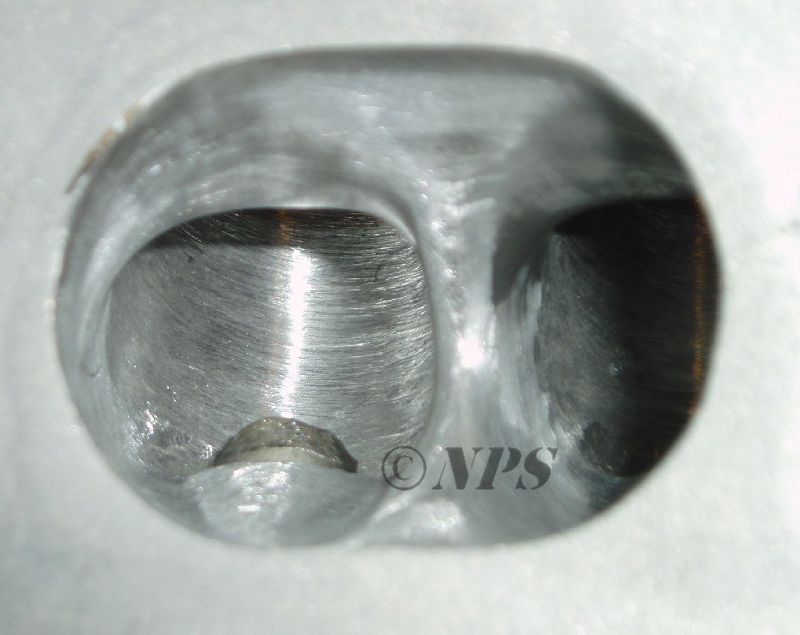

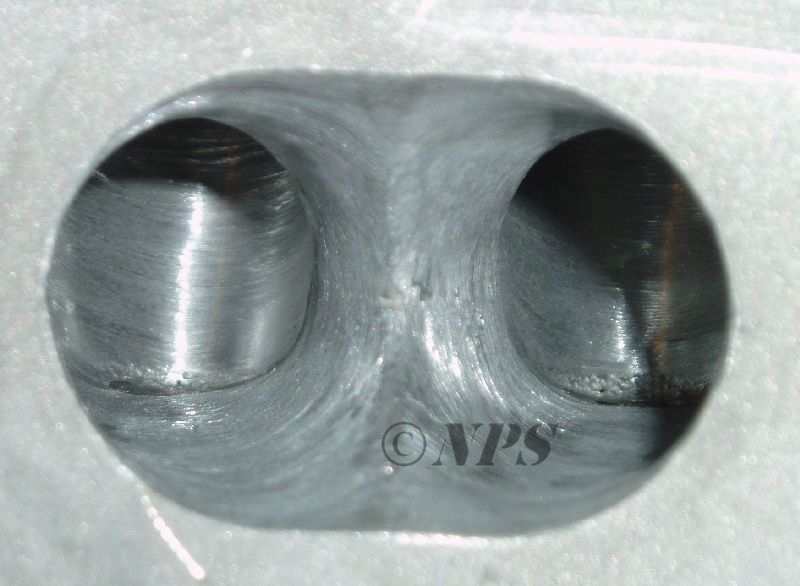

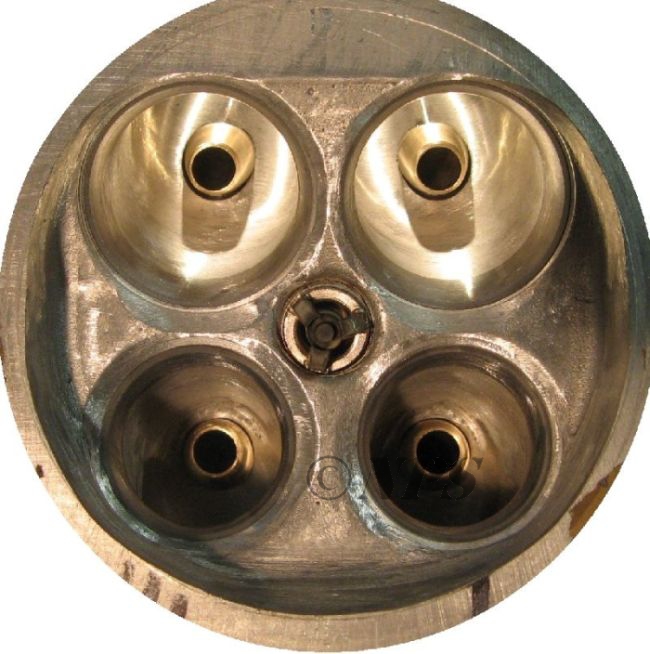

Ford Cosworth YB CNC:

Runner cross section areas and valve sizes can be adjusted for engine combination.

With stock valve size good to ~260hp naturally aspirated with fat Torque curve.

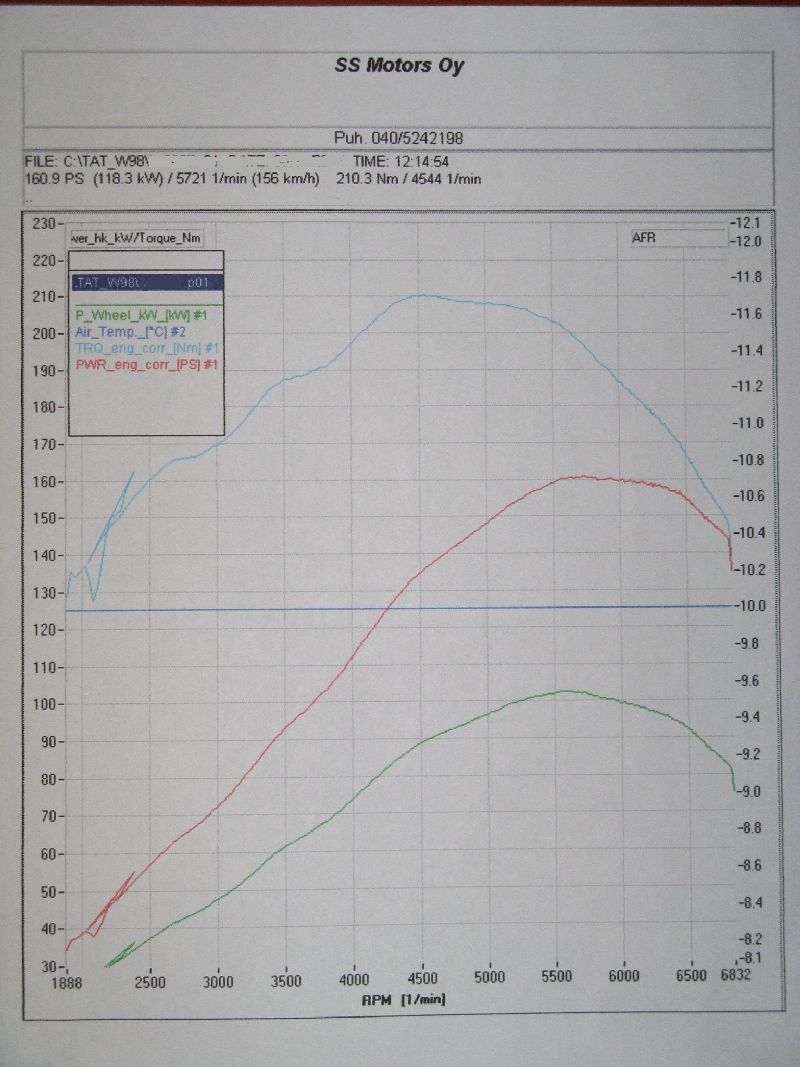

Opel CIH 2,0L:

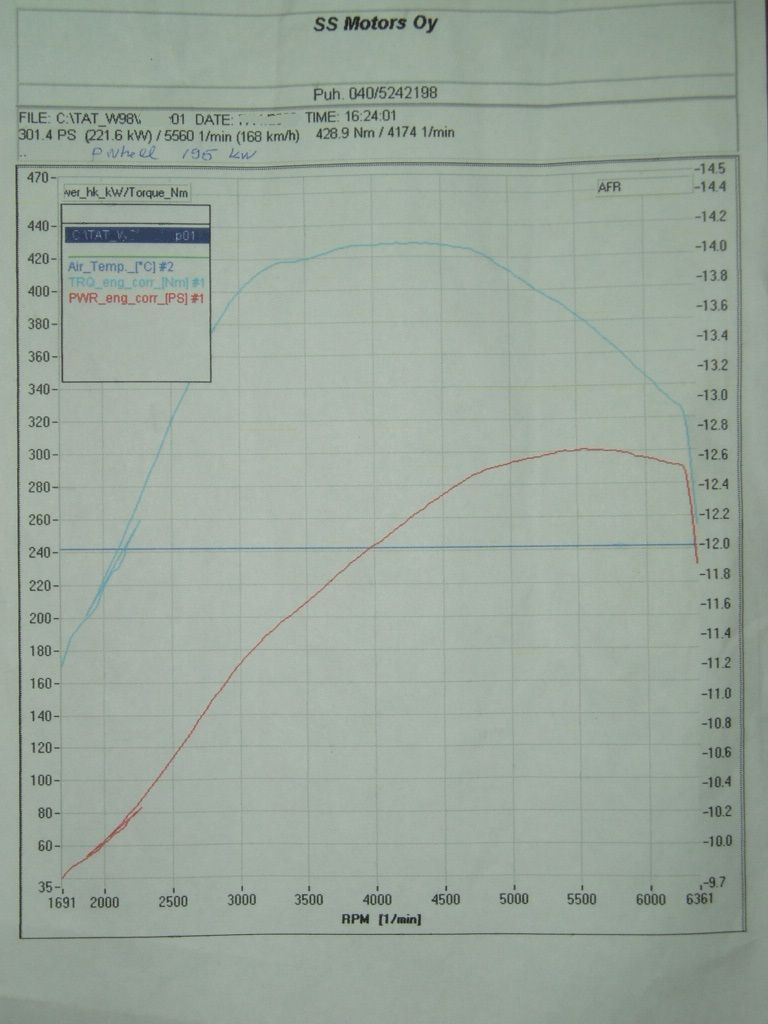

Audi S2 2.2L turbo:

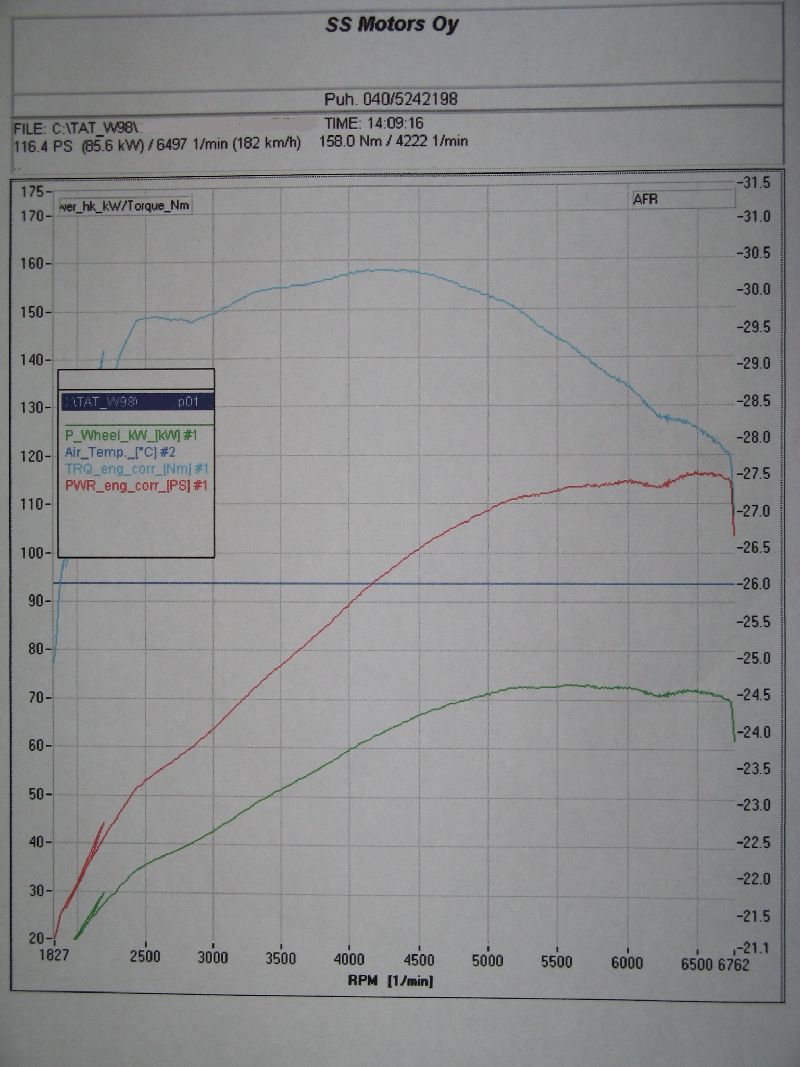

BMW 325:

Ford Escort Cosworth Rally F-group:

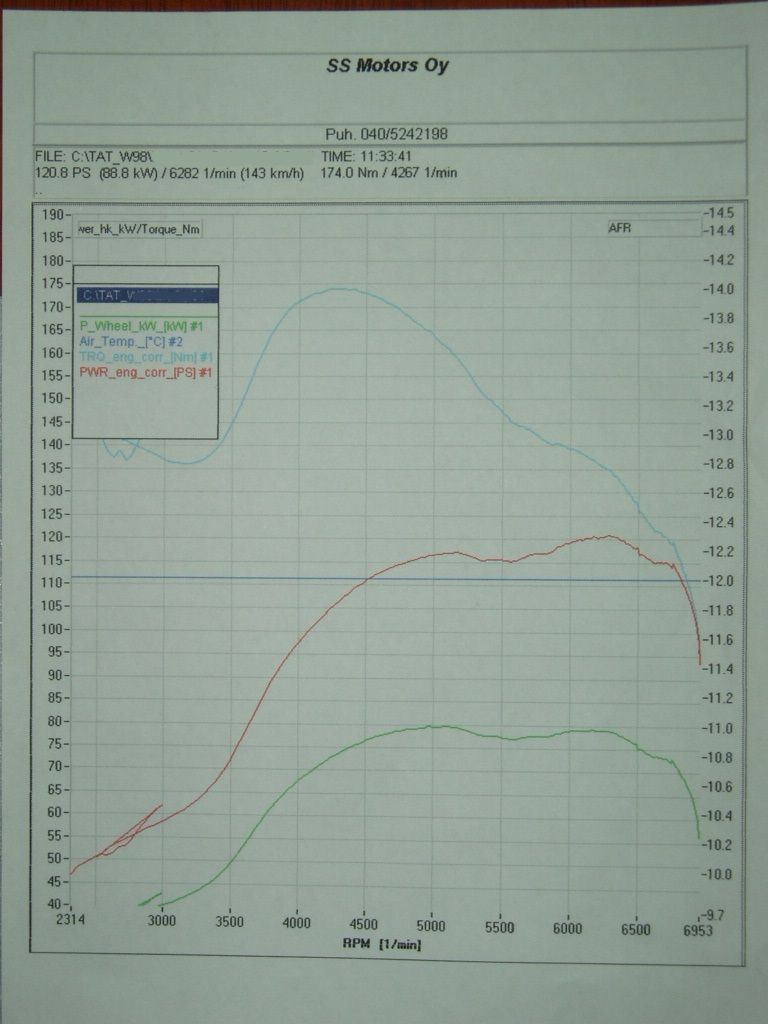

Ford Kent 1500 Historic Rally: